Blackall provides a unique value proposition

A former wool scouring location, Blackall’s wide open spaces and access to renewable energy sources (geothermal and solar) offers QWool a number of competitive advantages – allowing the Australian wool industry to optimise its supply chains and be sustainable from farm to factory.

Ideal Water Supply

Low-cost, naturally heated water from the Great Artesian Basin provides a major scouring cost advantage.

The water is clean, low-cost, and naturally at 62°C — ideal for wool scouring and significantly reducing operating expenses.

Efficient Domestic Logistics

Located on major trucking routes, the plant benefits from smooth and cost-effective wool transport.

Proximity to the Landsborough and Capricorn Highways allows efficient movement of greasy wool to the plant.

Low-Cost Land

Affordable land reduces capital costs and supports renewable energy and water re-use.

Compared to peri-urban areas, land here is far cheaper, enabling large-scale renewable energy installations and water management options.

Renewable Energy

Powered by solar and geothermal, the plant will operate near carbon-neutral with minimal energy costs.

A mix of solar electrical, solar thermal, and geothermal energy could eliminate purchased power needs and even allow energy export.

Water Re-Use

Process water can be recycled, lowering treatment costs and creating new revenue.

Beneficial re-use of process water removes effluent charges and provides additional income streams.

Solid Waste Re-Use

Re-purposing scour waste avoids disposal costs and adds further savings.

Solid waste can be redirected into productive uses, eliminating waste fees and improving efficiency.

Export Savings

Local scouring avoids expensive greasy wool exports to China, cutting major freight costs.

By processing in Australia, the plant removes the need for long-haul greasy wool shipments to Chinese scours such as Wuhan.

Local Wool Growth

Expanding sheep flocks will increase wool supply and support plant capacity.

Wild dog exclusion fencing has boosted lambing success from under 40% to over 85%, growing the regional wool clip.

Community Support

Strong local backing ensures regional benefits and alignment with government goals.

Blackall Tambo Regional Council, the Queensland Government, and local communities actively support the project, which also aligns with regional tourism growth.

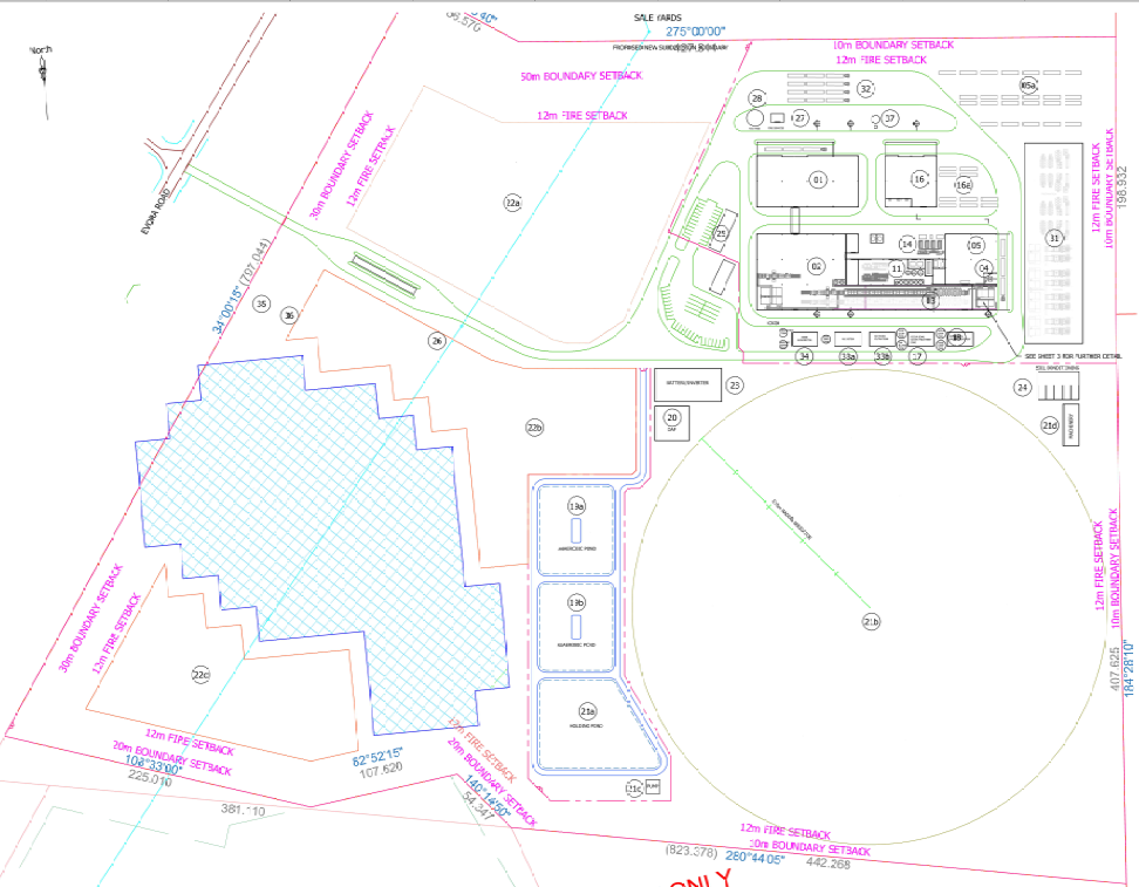

Blackall Scour – Site Layout

The Blackall Scour will be located adjacent to the historic Blackall Scour, will have its own bore from the Great Artesian Basin and be powered by renewable energy generated on-site. The site also has Type 2 road train access.

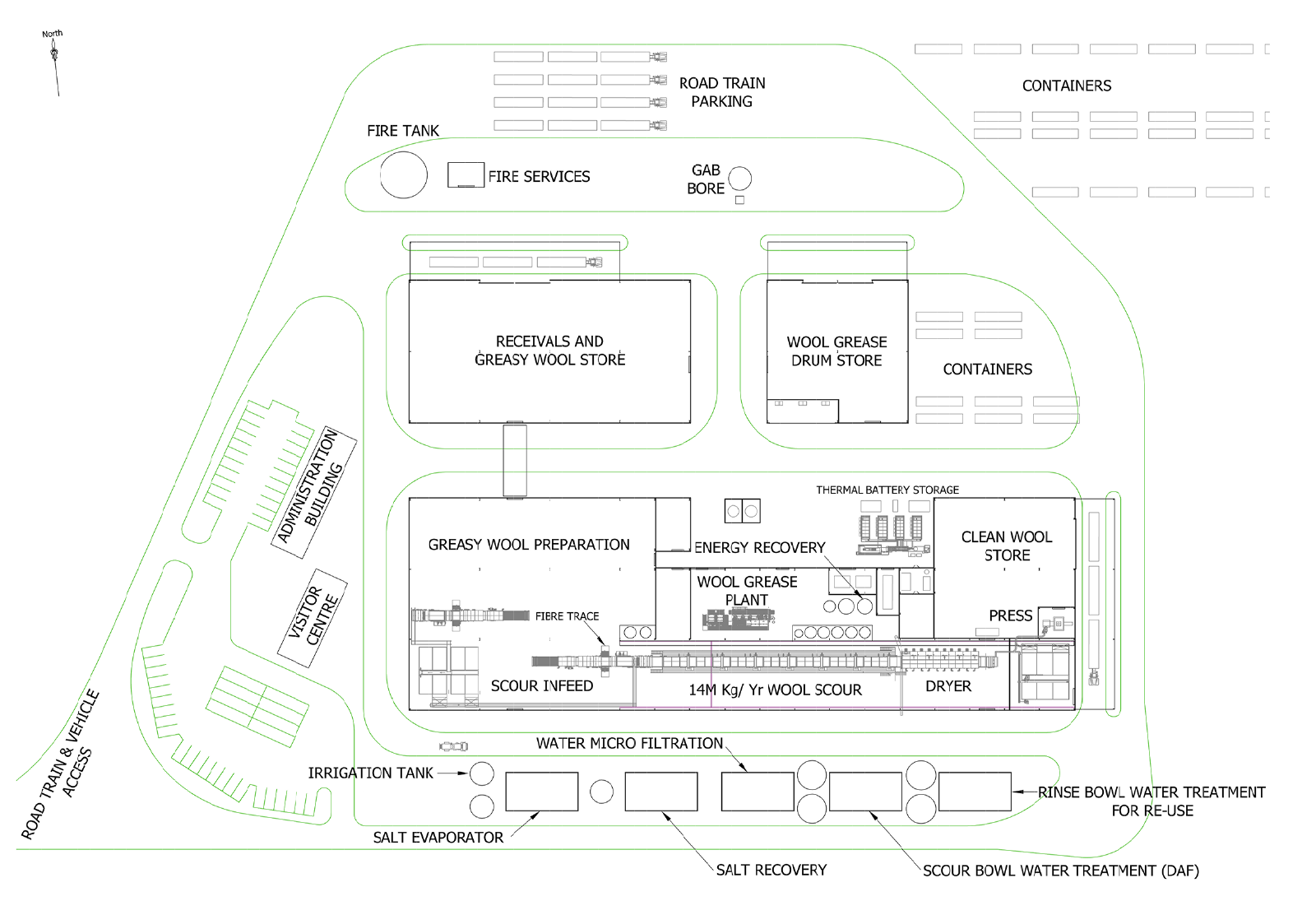

Blackall Scour – Plant Layout

The Blackall Scour will scour (clean) up to 14 million kg of Australian merino raw (greasy) wool to produce 9.1 million kilogram per year of scoured (clean) wool, and 1.2 kg of wool grease (Lanolin). Potassium salts will also be recovered from wastewater and converted to a fertilizer product.

Planned workforce

The Blackall Scour will employ a primarily local Central West workforce (44 of 48 staff), using flexible “lifestyle” rosters to support rural livelihoods. With wool processing skills lost over 40 years, training will be provided from Italian experts and equipment suppliers to build local workforce capability and knowledge.

We have an ambitious target to grow agriculture in this state, and it starts here in Blackall.”

Hon Tony Perrett MP

Minister for Primary Industries